Exair 5215 Standard Cold Gun System (One Cold Outlet)

- Specification

- Overview

- Customers Also Bought

- Your Recently Viewed Items

- Reviews

- $472.72 / Kit

- Brand:Exair

- Part #:5215

- Regular Price:

$508.00 - $472.72 / Kit

Overview

The Cold Gun Aircoolant System with a single point hose kit produces a stream of clean, cold air at 50°F (28°C) below supply air temperature. This system includes the Cold Gun, flexible single point hose assembly and manual drain filter separator. Available in standard or high power versions. Operation is quiet and there are no moving parts to wear out. It will remove heat to prolong tool life and increase productivity on machining operations when liquid coolant cannot be used. Because it uses vortex cooling, the Cold Gun is also an alternative to expensive mist systems by eliminating the costs associated with the purchase and disposal of cutting fluids as well as worker related health problems from breathing airborne coolants or slipping on wet floors.

Applications

- Tool sharpening

- Drill and cutter grinding

- Routing

- Plunge and form grinding

- Milling

- Surface grinding

- Drilling

- Tire grinding

- Band sawing

- Plastic machining

- Laser cutting

- Chill rolls

- Setting hot melt adhesives

Advantages

- Improves production rates

- Prevents burning

- Extends tool life - reduces breakage

- Improves tolerance control

- Prevents smearing of metal or plastics

- Finished part is dry

- Eliminates wheel loading

- Low cost

- Compact, lightweight, portable

- No moving parts - maintenance free

- Quiet

- No coolant cost

- No electricity

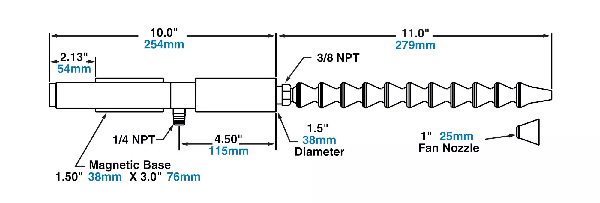

Cold Gun Dimensions

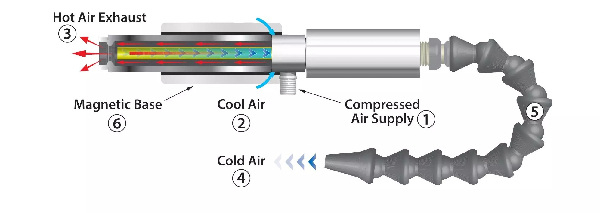

How the Cold Gun Works

The standard Cold Gun and High Power Cold Gun incorporate a vortex tube to convert an ordinary supply of compressed air (1) into two low pressure streams, one hot and one cold. Secondary air is drawn in (2). The Cold Gun's hot airstream is muffled and discharged through the hot air exhaust (3). The cold air (4) is muffled and discharged through the flexible hose (5), which directs it to the point of use. Easy mounting and portability are provided through the use of an attached magnetic base (6).