Exair 2603 3" Aluminum Full-Flow Air Knife

- Overview

- Customers Also Bought

- Your Recently Viewed Items

- Reviews

- $173.25 / Each

- Brand:Exair

- Part #:2603

- Regular Price:

$175.00 - $173.25

Overview

The Full-Flow Air Knife borrows engineering elements from original Standard Air Knife with the added benefit of an airflow across its entire length, but will have higher operating costs than the Super Air Knife. They also provide the smallest footprint of Air Knife line to fit in cramped machine spaces. These are a low cost choice and are available from stock in 3" length. The Full-Flow Air Knife is available in aluminum.

Applications

- Part drying after wash

- Sheet cleaning in strip mills

- Conveyor cleaning

- Part or component cooling

- Web drying or cleaning

- Environmental separation

- Pre-paint blowoff

- Bag opening/filling operations

- Scrap removal on converting operations

Advantages

- Up to 10 dBA noise reduction

- Reduced air consumption

- 30:1 air amplification

- Aluminum

- Compact, rugged, easy to install

- No moving parts

- Compressed air inlets on each end

- Variable force and flow

How the Full-Flow Air Knife Works

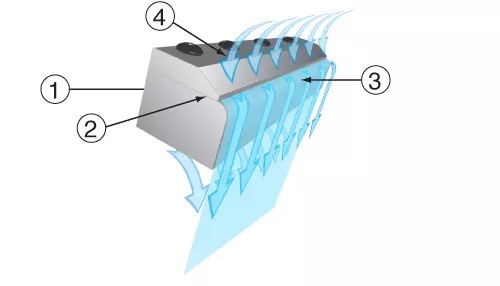

Compressed air flows through the inlet (1) into a plenum chamber. It is then throttled through a thin nozzle (2) extending the length of the Full-Flow Air Knife. This primary airstream adheres to the Coanda profile (3), which turns it 90° and directs the flow down the face of the unit. The primary stream immediately begins to entrain surrounding air (4), for an amplification ratio of 30:1 at 6" (152mm) away.

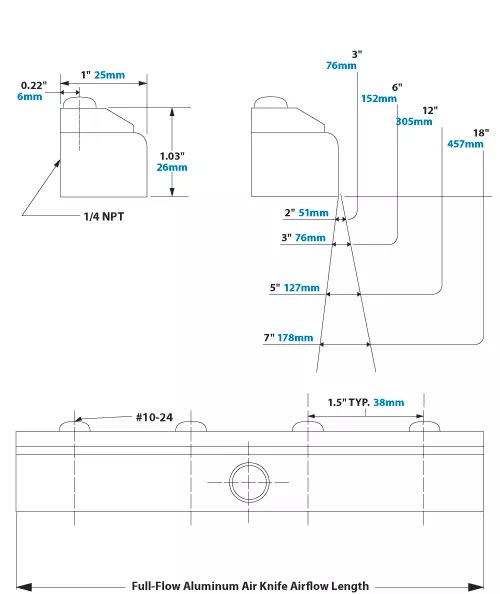

Full-Flow Air Knife Dimensions and Airflow