Weber Sensors 4321.13/18 Flow-Captor Inline Flow Switch for Oil-Based Media with Transistor Output PBTP (18mm Pipe Diameter) Switched Flow > Point

- Specification

- Overview

- Customers Also Bought

- Your Recently Viewed Items

- Reviews

- $1,222.80 / Each

- Brand:Weber Sensors

- Part #:4321.13/18

- Model #:Flow-Captor

- Regular Price:

$1,318.35 - $1,222.80

Overview

Flow switch for oil-based media Flow-captor 4321.13/18

The flow-captor type 4321.13/18 is a flow monitor which is used in automation processes and other industrial applications where liquid media need to be monitored. This series offers "inline-models" that have been specially designed for installation in smaller pipe diameters. The sensor works according to the calorimetric measuring principle. The detection takes place inside the inline tube, whereby the sensor measures the flow velocity of the medium and converts it into an electrical signal.

Features:

- For small pipe sizes

- Precise switching flow sensor with high accuracy even with slower flows

- Separate adjustment of flow range and switching point

- Analogue display of flow condition and adjusted switch-point via LED chain

- Electronic function without any mechanically moved parts

- Robust industrial design (special potting)

- ISO 9001:2015

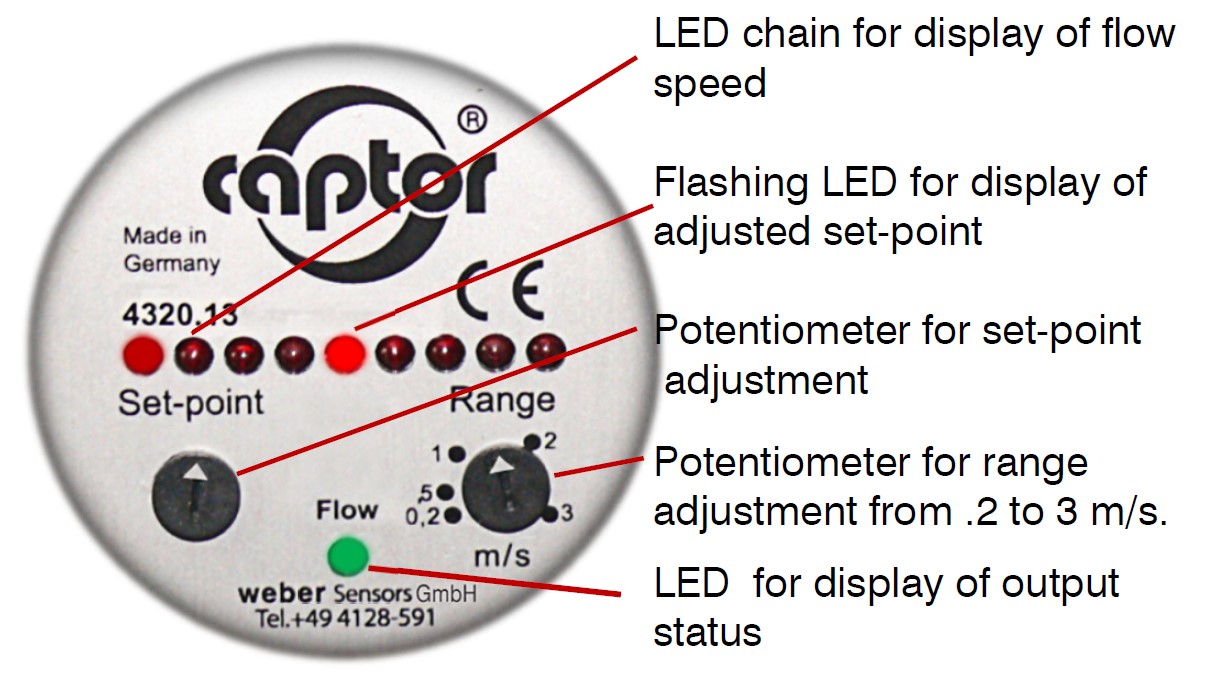

Control and display panel

The sensor tube

The sensor tube is made of stainless steel 316 and is an integral part of the inline flow-captor.

Free flow

The sensor element of the inline flow-captor is fitted to the out-side of the sensor tube. Since there is no element inside the tube, the sensor is non-intrusive to the flow. The robust housing is constructed of glass fiber reinforced PBTP (Ultradur ®). The electronics housing includes a full resin encapsulation.

Mechanical connection

Cutting ring couplings, to be ordered separately, have proven their value when mounting the sensor into pipe systems. By slightly tightening the swivel nut the v-shaped ring inside of the coupling cuts into the sensor tube wall and thus ensures a dense and reliable form closure.

For more information, please see Instruction Manual and Data Sheet