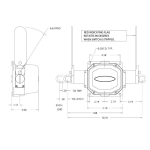

Rees 04954-204 Cable Operated Switch with Flags

- Specification

- Overview

- Customers Also Bought

- Your Recently Viewed Items

- Reviews

Overview

Features:

The following "slack cable" style switch has 2 NO and 2 NC contacts on each end. This switch is particularly competent for use in Emergency Stop applications as well as for ordinary circuit control.

The housing is made from high quality die-cast aluminum and powder coated painted yellow. The independently operating red indicating flags rotate 90 degrees when tripped. Manually returning the flags to their normal position resets the switch.

- Manual reset with "Positive Break" contacts

- Gold plated contacts eliminate high resistance tarnishing

- Bi-Directional with Dual Flags

- Nema 4X (indoor), IP 66

Each captive terminal will accept (2) #14 AWG stranded wires. Each switch is supplied with a fibreflex gasket which provides an oil tight seal upon installation. For added protection against corrosive environments a neoprene gasket is available as an accessory item by ordering part number 02005-540.

There are two 3/4 NPT conduit openings. The maximum cable recommended cable length is 200 feet per end with a maximum interval support of 10 feet.

The mechanical life of the switch is 150,000 operations.

This switch can be installed on various conveyor installations and provides a constant access for emergency or normal stopping.

The rugged construction and long term reliability makes this cable pull switch well suited to function within various environments.

Electrical Ratings:

- "HEAVY DUTY - A600 / N150"

- Listed under UL 508 - File # E 58589

- Certified under CSA C22.2 - File # LR 3648

- CE Compliant IEC/EN 60947-5-1

Environmental Temperature Range

- Operating: +32°F to +131°F (0°C to +55°C)

- Storage: -40°F to +185°F (-40°C to +85°C)

- Note: Operating temperatures at 0oC are based on the absence of freezing moisture and liquids.

WARNING

These products should only be used where point-of-operation guarding devices have been properly installed & maintained so that appropriate OSHA and ANSI B11.1 regulations & standards are met. Misapplication of the products on machinery lacking effective point-of operation safeguards can cause serious injury to the operator of that machinery.