Exair 4804 NEMA 4 Cabinet Cooler System with Thermostat Control (275 Btu/hr)

- Specification

- Overview

- Customers Also Bought

- Your Recently Viewed Items

- Reviews

Overview

NEMA 4 (IP66) thermostat control systems are the most efficient way to operate a Cabinet Cooler. They save air by activating the cooler only when internal temperatures approach critical levels. Thermostat controlled cooler systems are the best option when experiencing fluctuating heat loads caused by environment or seasonal changes. Standard thermostat control systems include an adjustable thermostat factory set at 95°F (35°C). NEMA 4 (IP66) Cabinet Cooler Systems (dust-tight, oil-tight, splash resistant, indoor/outdoor service) incorporate a low pressure relief valve for both the cooler and cabinet air exhaust. This valve closes and seals when the cooler is not operating to maintain the NEMA integrity of the electronic enclosure. NEMA 4 (IP66) Cabinet Coolers are available in many cooling capacities for large and small control panels. Unlike an expensive, freon-based air conditioner, EXAIR Cabinet Coolers incorporate a vortex tube to produce cold air from compressed air - with no moving parts. They can be installed in minutes through a standard electrical knockout. Each of these systems include a water-dirt filter separator to prevent water condensate and dirt from entering your enclosure and a cold air distribution kit used to direct the air for circulation or on to hot spots. All Cabinet Coolers are UL Listed and CE compliant.

Applications

- Programmable controllers

- Line control cabinets

- Motor control centers

- Relay panels

- NC/CNC systems

- Modular control centers

- CCTV cameras

- Computer cabinets

- Cool laser housings

- Electronic scales

NEMA 4 Cabinet Cooler Advantages

- Low cost

- Compact

- Cooling capacities up to 275 Btu/hr. (80 Watts)

- Quiet

- Install in minutes

- Maintain NEMA 4 integrity (IP66)

- Stabilize enclosure temperature and humidity

- No CFC's

- No moving parts - maintenance free

- Mount in standard electrical knockout

- Stop nuisance tripping

- Stop heat damage

- Eliminate fans and filters

- Eliminate lost production

- Stop circuit drift

- Stop dirt contamination

- Provide washdown protection

What is an EXAIR Cabinet Cooler System?

EXAIR Cabinet Coolers are a low cost, reliable way to cool and purge electronic control panels. They provide air conditioning for the electrical enclosures, eliminating electronic control downtime due to heat, dirt and moisture! These panel cooling systems for enclosures incorporate a vortex tube to produce cold air from compressed air with no moving parts.

The compact Cabinet Cooler is an easy-to-use air conditioner that can be installed in minutes through a standard electrical knockout.

Why EXAIR Cabinet Coolers?

When the electronics inside a control cabinet overheat, the machine can shut down due to tripped overloads and breakers or heat damage to the circuit boards. Unreliable cooling methods such as fans, heat exchangers, refrigerant air conditioners, and heat pipes are prone to failure as a result of mechanical wear, and clogged filters.

EXAIR Cabinet Coolers provide cold air for large and small control panels and are maintenance free. They have no moving parts to wear out. All Cabinet Coolers are UL, ULC Listed and/or CE compliant.

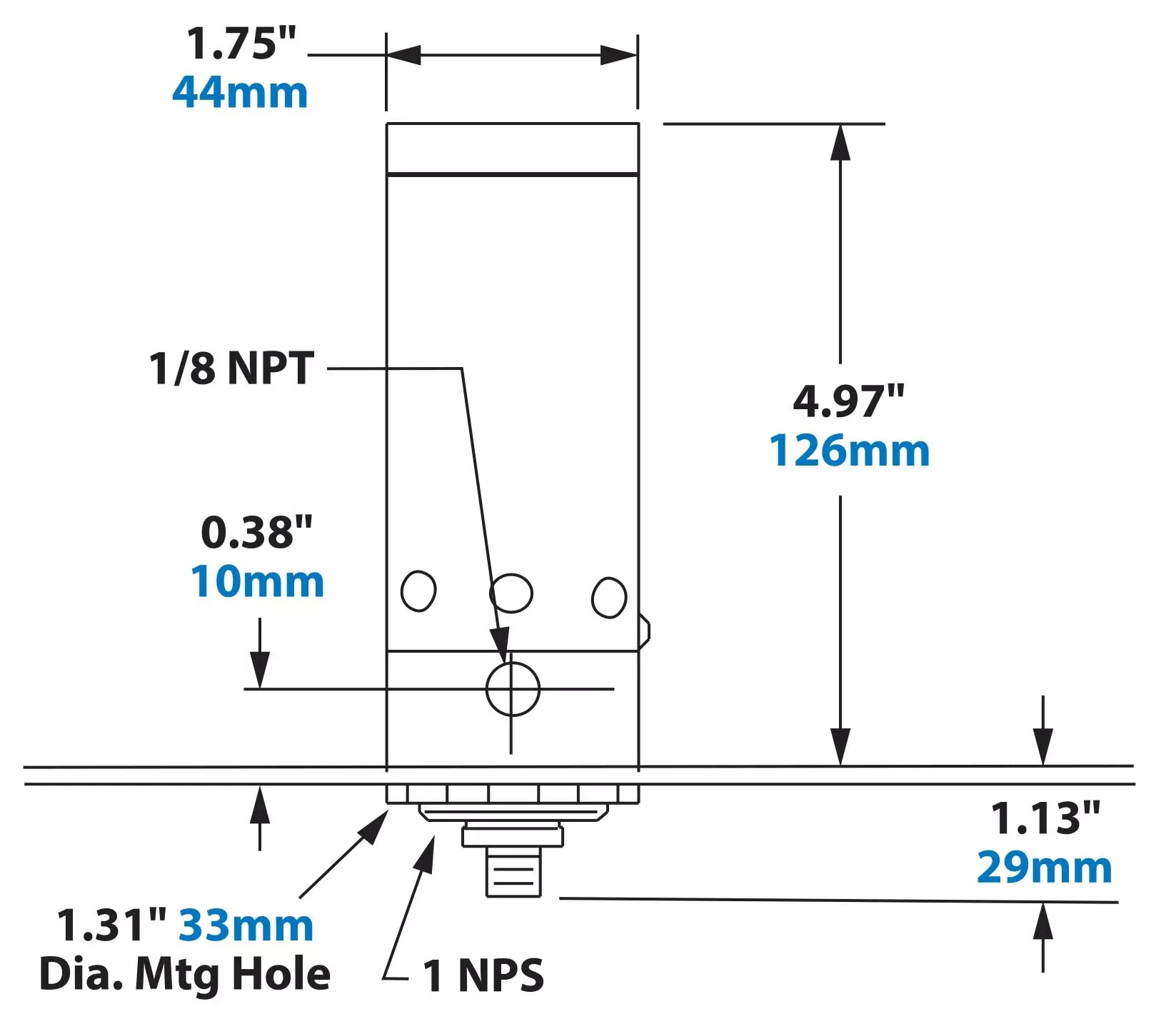

Dimensions - NEMA 4 Cabinet Coolers

How Cabinet Coolers Work

Compressed air enters the vortex tube powered Cabinet Cooler and is converted into two streams, one hot and one cold. Hot air from the vortex tube is muffled and exhausted through the vortex tube exhaust. The cold air is discharged into the control cabinet through the cold air distribution kit. The displaced hot air in the cabinet rises and exhausts to the atmosphere through the cabinet air exhaust at a slight positive pressure. Thus, the control cabinet is both cooled and purged with cool, clean air. Outside air is never allowed to enter the control panel.