Frequently Asked Questions

Where are safety labels needed and what are they for?

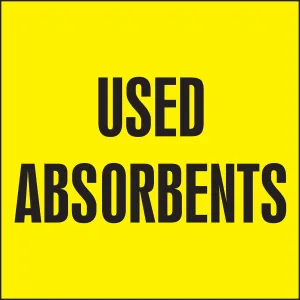

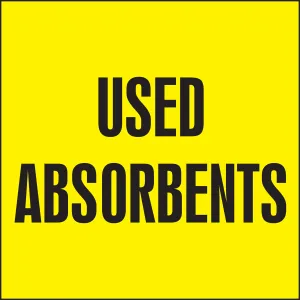

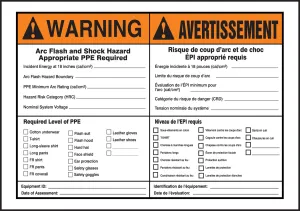

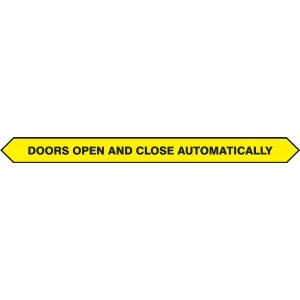

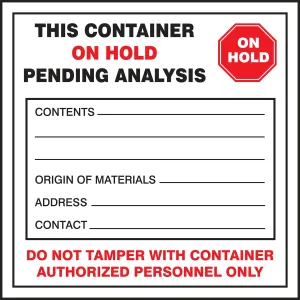

Safety labels are used on machines, doors, panels, and storage areas to flag hazards before work starts. They are needed wherever there is a real risk of injury from moving parts, electricity, heat or chemicals. For equipment isolation, combine with lockout tagout procedures and devices.

What does a safety label need to meet OSHA/ANSI?

A label should have a signal word, name the hazard, say what could happen, and give clear steps to stay safe. Good safety warning labels stay short, specific, and easy to read in the real work area.

How should colors, signal words and symbols be chosen?

Which materials withstand chemicals, UV, and abrasion?

For harsh areas, choose industrial safety labels made from polyester or vinyl with UV-stable inks and a clear overlaminate. High-tack acrylic adhesive helps on textured or outdoor surfaces. Check temperature and solvent resistance in the datasheet.

Where is the best place to put safety labels?

Place safety labels close to the hazard, at about eye level if possible, on a clean flat surface. The person should notice the message before touching controls, opening a panel or entering the danger zone.